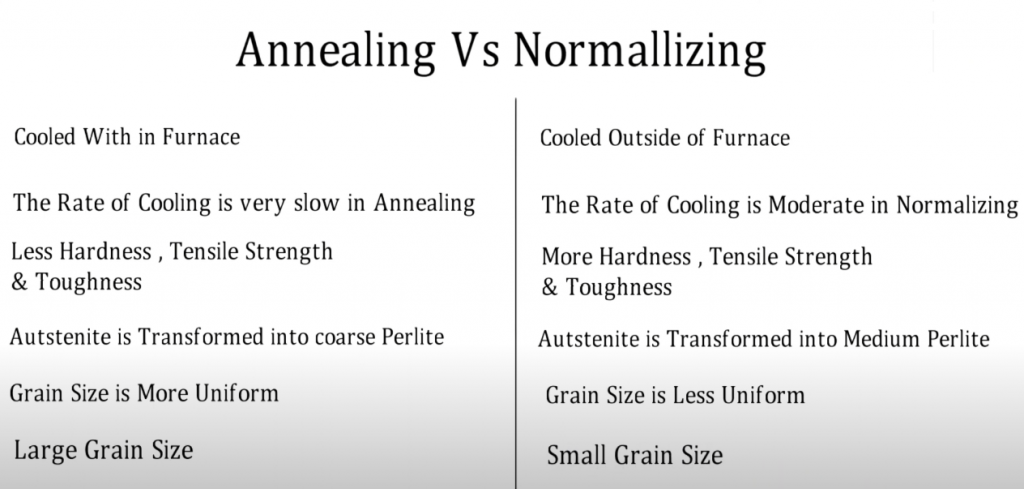

Annealing is a warmth therapy procedure that includes heating a product to a details temperature level where atomic flexibility boosts, enabling for the relief of internal stresses, decrease of firmness, and enhancement of ductility. This process properly changes the microstructural structure of the steel, enabling the arrangement of atoms to redistribute themselves into a state of reduced power. Usual steels undergoing annealing consist of light weight aluminum, copper, and steel, where the variations of annealing-- such as full annealing, procedure annealing, and spheroidizing-- produce different results based on the details demands of the application.

In comparison, stabilizing is also a warm therapy process however is primarily utilized to improve the grain structure of a steel and attain an uniform and wanted mechanical property throughout. The procedure advantages from a higher cooling price, which affects the final microstructure, resulting in a finer and even more consistent arrangement of grains contrasted to steels treated with annealing. It is an especially efficient therapy for ferrous alloys, such as carbon steels, where attaining high-performance material residential properties like return strength and tensile stamina is commonly necessary for industrial applications.

Check out annealed vs normalized the critical distinctions between annealing and normalizing in metallurgy, 2 essential heat treatment processes that dramatically influence the mechanical residential or commercial properties and efficiency of steels and alloys in various applications.

While both processes share similarities, they are chosen based on the specific homes needed for a designation or application of the material. In producing processes where improved mach inability, good formability, or enhanced ductility is desirable, products are more likely to undergo annealing.

Throughout various industries, annealing and normalizing serve substantial duties. For circumstances, in the auto field, while several parts are made with casting or creating, subsequent warm treatments are important. Annealing is frequently used for steel components, such as equipments and shafts, to enhance resistance against weak fracturing, which might arise from welding processes or functional pressures throughout their solution life. Normalizing finds extensive applications in structural parts for structures and equipment, where the enhancement of mechanical homes under loading problems is of utmost value. This microstructural refinement fosters improvements in yield toughness and sturdiness, therefore prolonging the life expectancy and performance capabilities of these products.

Both warm therapy processes additionally highlight the balance in between achieving preferred physical properties and enhancing productivity. Both processes call for careful factors to consider not just for accomplishing optimum microstructure but additionally for integrating well within the manufacturing line, inevitably impacting financial viability and sustainability.

Additionally, the details of annealing versus normalizing locate relevance in research study and academic community, where a deeper understanding of products can lead to improvements in design practices. As an example, in light-weight yet sturdy applications, such as aerospace and vehicle components, the tactical application of different warmth treatments can considerably influence product selection. Study efforts typically dive right into the end results of both processes and create maximized methodologies that blend treatment methods, permitting for cutting-edge solutions that satisfy the ever-evolving needs of modern-day sectors.

One must likewise stress the ecological implications surrounding using warm therapies like annealing and normalizing. With expanding awareness of sustainability and energy effectiveness within producing procedures, initiatives are underway to minimize the ecological footprint of these standard approaches. Innovations in heat treatment innovations, consisting of the growth of much more efficient furnace and optimization of cycle times, play a critical duty in reducing emissions and energy usage. Engineers and scientists are proactively going after methods to make therapy techniques greener, assessing power usage throughout procedure cycles, and including renewable resource sources where possible. This change towards more sustainable practices not only highlights the relevance of annealing and normalizing in producing excellent materials however highlights the requirement to raise sector criteria past plain mechanical efficiency and right into ecological stewardship.

In terms of building contrasts, annealed and normalized products offer distinctive benefits owing to their integral microstructural qualities. This aberration lights up the fragile interaction in between microstructure and the final features of a product, making it vital for specialists in metallurgy or design to review their options with both techniques in mind.

As advancements in materials scientific research remain to evolve, the interplay in between procedures impacts the r & d of new alloys and composites. Scientists are constantly discovering mixes and additives that change thermal therapy processes, bring about the design of innovative materials that exhibit novel efficiency attributes. The classic principles discovered in annealing and normalizing stay foundational as scientists pivot toward the future generation of crafted materials. As these examinations unravel, the utility and understanding bordering typical warm therapy processes will proceed to adjust, achieving progressively sophisticated applications.

In understanding these essential procedures within warm therapy, specialists rally a deeper comprehension that serves not only their instant functions however adds to more comprehensive progression across industries. As the complexities of the material world will certainly constantly give obstacles, the mastery of annealing and normalizing processes will be important, making sure the toughness and sustainability of crafted parts. Via these understandings, we cultivate a future where the principles rooted in these thermal treatments guide us toward innovative options and durable applications that reverberate throughout all markets of culture, consequently strengthening the extremely important value of these procedures in our day-to-day lives.